DOWNLOAD THE PRODUCT CATALOG |  |

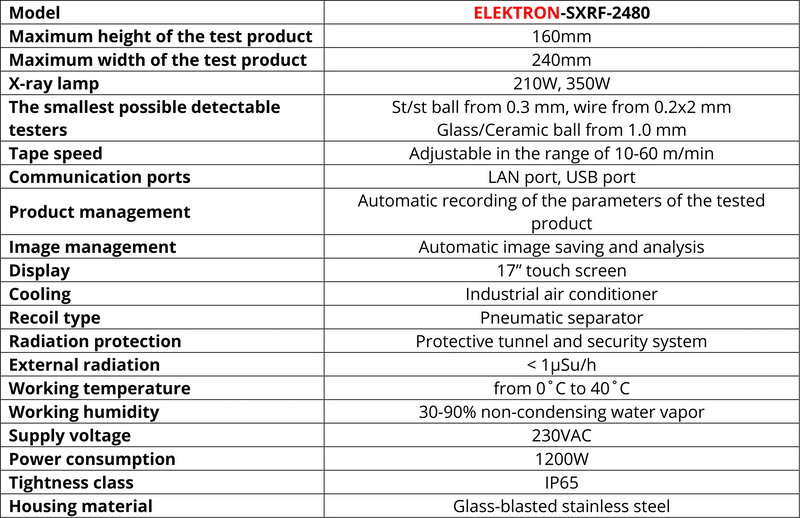

PARAMETERS

APPLICATION

- ready-made products, e.g. pizza, casseroles,

- fruits and vegetables - fresh and frozen,

- products in low metal cans, e.g. fish, canned food, peas, beans,

- meat products

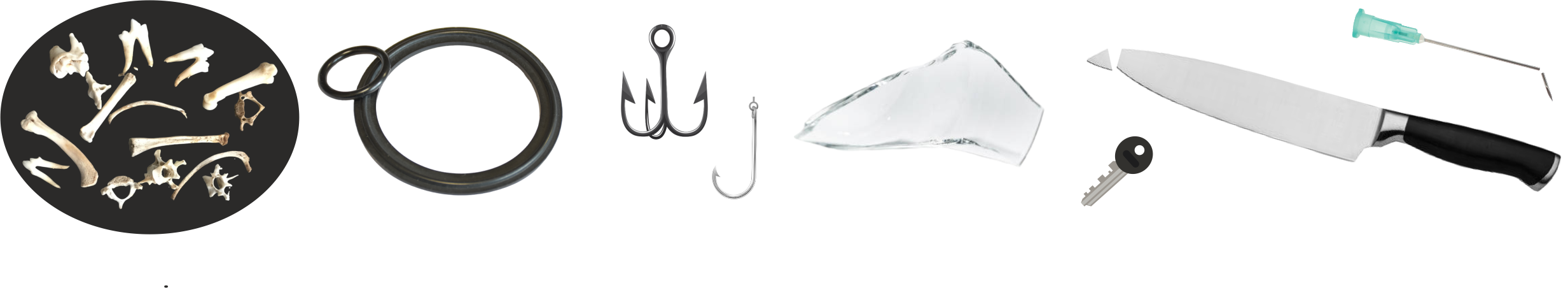

FOREIGN BODY DETECTED

MAIN FEATURES

- Very high level of detection and unparalleled operating stability when scanning products of different shapes entering irregularly or even drifting.

- Touchscreen for easy operation and management of functions (possibility to fine-tune manual parameter settings).

- Detection of all metals, stones, glass, ceramics, rubber, hard plastics.

- Intuitive and simple operation.

- Smooth management of each detection zone increasing the level and quality of scanning.Remote 24-hour service support regardless of location.

SYSTEM FUNCTIONS

- 2 password-protected access levels.

- The operator can manually adjust the settings.

- Detection of defective products with damage (deformed product, crumpled can, no product or defective product).

- Built-in weight controller - X-Ray scanner eliminates products with incorrect weight from 1-5 grams depending on the type of product.

- Possibility of cooperation with any separator.

- Automatic diagnostics and safety control system (detection of open inspection doors in the device and immediate stopping of the device and turning off the X-Ray lamp radiation).

„FROST” SYSTEM

The X-Ray scanner can be equipped with a unique "FROST" system with a built-in intelligent heating system and a thermostat inside the control panel, which protects the internal electronics against moisture and cold. It is the only protection against rapid temperature changes during washing and protects against moisture absorption inside (for example, a cold machine washed with hot water).