DOWNLOAD THE PRODUCT CARD |  |

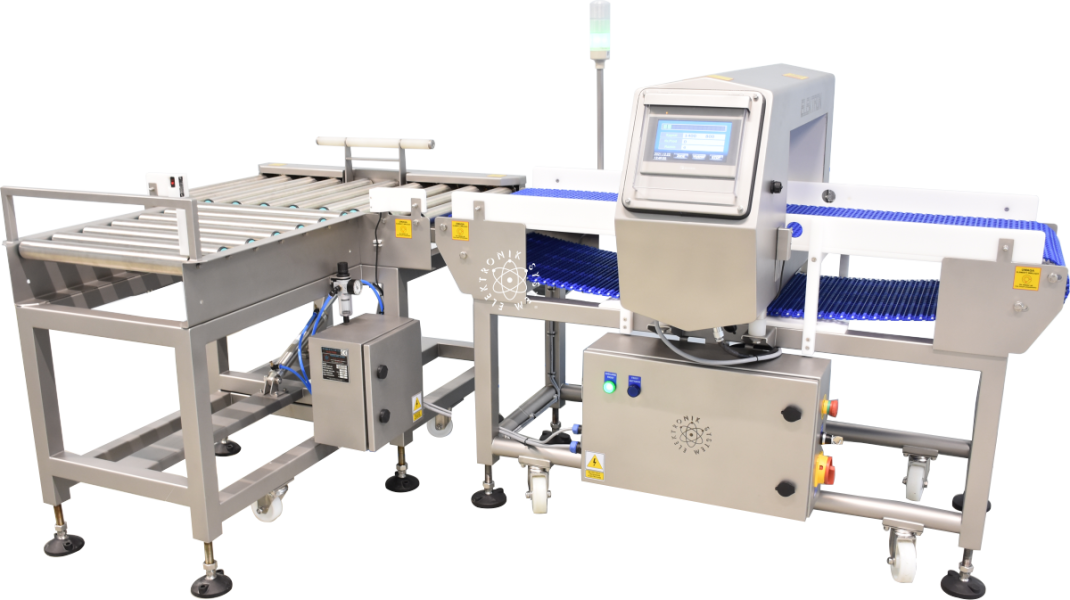

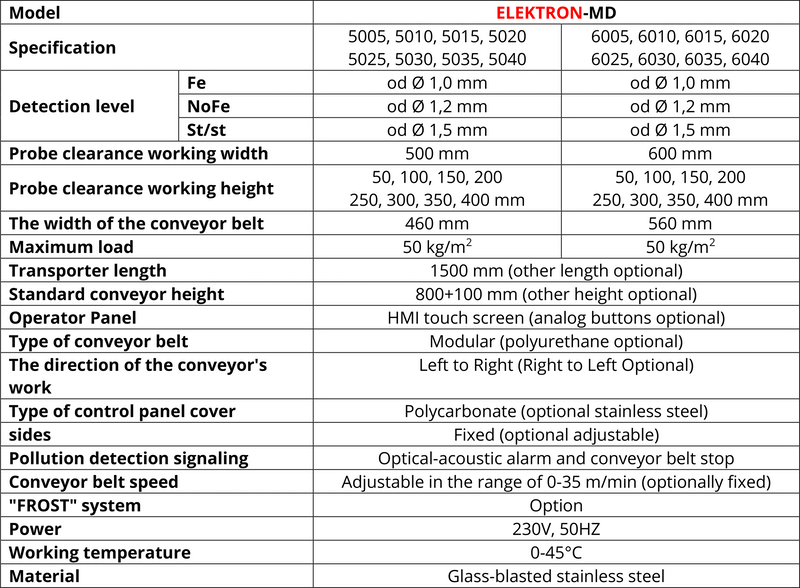

PARAMETERS

APPLICATION

Metal detectors for large products are designed to test products packed in all types of packaging, free of metal or for products served in bulk (without packaging). Our devices are dedicated to work with products such as:

- meat, sausages, fish, seafood - fresh and frozen,

- semi-finished meat and fish intended for milling,

- vegetables and fruits - fresh, frozen and processed,

- dairy - milk, cheese, cream, etc.,

- bakery and confectionery products - bread, rolls, cookies, etc.,

- ready-made products - ready-made dinner dishes, e.g. dumplings, noodles, etc.

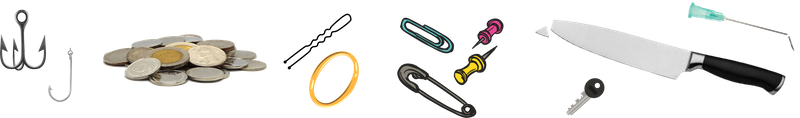

FOREIGN BODY DETECTED

WHAT MAKES US STAND OUT?

- 10 years warranty for the metal detector probe,

- a unique system of contactless self-learning,

- built-in auto-calibration system - no periodic inspections required,

- "FROST" system,

- high level of detection and problems in the organization's work

Touchless auto-learning system

The ELEKTRON-MD series of detectors has a non-contact auto-learning system, unprecedented in other detectors. The non-contact auto-learning system analyzes the tested product and automatically saves the detection parameters (e.g. the influence of the product itself and the background of the environment). The detector, controlling the transporter, automatically moves the product through the detection probe window back and forth until the learning is completed. This solution facilitates work, especially with heavy products. Thanks to this, learning is much more accurate without interference and also increases the level of detection and stability of the metal detector.

Auto-calibration system

Our metal detectors have a built-in auto-calibration system, thanks to which the devices do not require constant service inspections. The detection system accurately oscillates at the frequency of the test substance, adjusts itself to variable values. The management system is designed so that each time the detector is disconnected from the network for about 15 minutes, it automatically performs a background analysis and self-calibration of the system after restarting.

"FROST" system

Our metal detectors can be equipped with a unique "FROST" system with a built-in intelligent heating system and thermostat inside the control panel, which protects the internal electronics from moisture and cold. It is the only protection against rapid temperature changes during washing and protects against moisture absorption inside (for example, a cold machine washed with hot water). Operation of the machine in a cold room and with a frozen product.

SYSTEM FUNCTIONS

- Menu in Polish and English (standard).Optional menu in all other languages indicated by the client.

- Detection and alarm history, date and time.

- USB port for reading data to a pendrive.

- Memory function for testing 100 different ones products.

- Auto learning system.

- Automatic system self-calibration.

- Automatic correctness enforcement system detection.

- Stopping and reversing the tape upon detection metal - optional.

- Password protected access levels.

- Confirmation of discharge of contaminated product and full container signal.

TYPES OF SEPARATORS