PARAMETERS

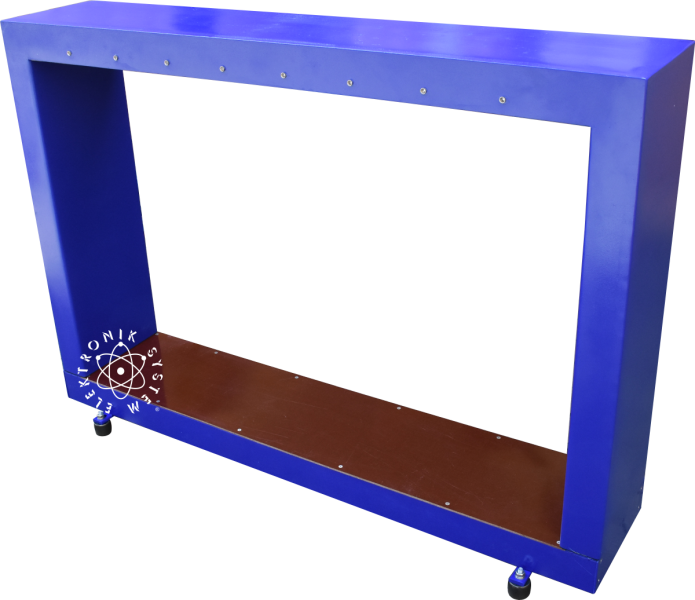

Model | ELEKTRON-NMD-8040 |

Total height of detection | 400 mm |

Overall detection width | 800 mm |

Detection method | magnetic induction |

Beacon | optical-acoustic |

Alarm method | A set of diodes indicating the exact detection zone, |

Control output (e.g. stopping the conveyor belt) | |

The speed of the conveyor belt is adjustable | 0-32m/min |

Electric source | AC100-240V, 50-60HZ |

Power consumption | 170W |

Dimensions | 1200 mm x 260 mm x 700mm |

Libra | 190 kg |

MAIN FEATURES

very easy and friendly operation of the detector thanks to the use of a clear operator panel,

probe LEDs located on the detection probe, which indicate the exact location of the contamination. The solution allows you to save working time and test material,

smooth and simple sensitivity adjustment,

smooth sensitivity adjustment,

- real-time detection (dynamic),

solid construction resistant to use in industrial conditions,

in the case of contamination of the tested product with iron from 0.8, the indicator will indicate its presence,

the LED on the probe housing will indicate the contamination zone,

the detector has an output for controlling external devices (e.g. conveyor belt).