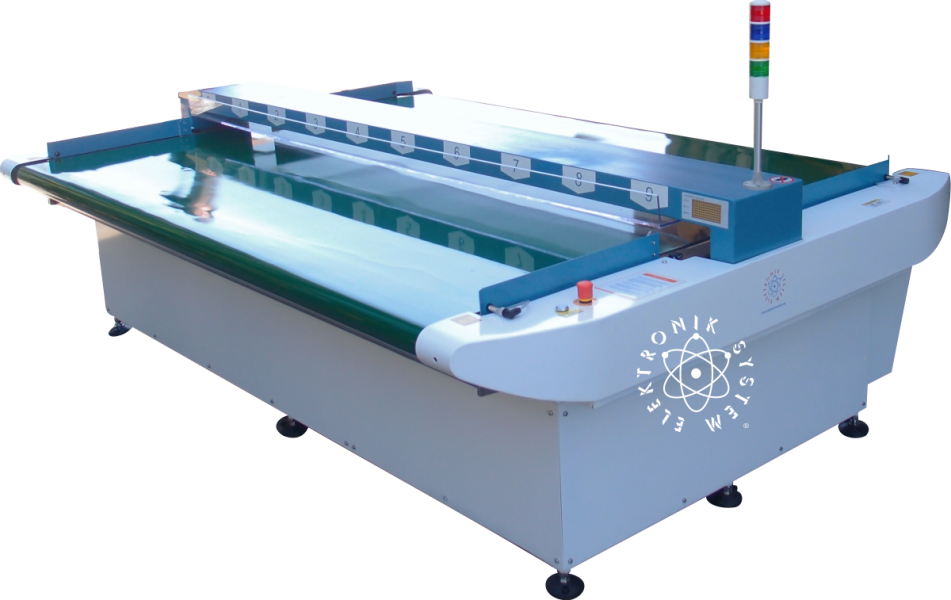

ELEKTRON-NMD-25010 designed for the knitting, pharmaceutical, chemical and rubber industries. Its task is to detect needles and shards of needles inserted into inspected products, such as clothing, mattresses, covers or upholstery.

PARAMETERS

Model | ELEKTRON-NMD-25010 |

Working height detection | 60 mm |

Detection working width | 2500 mm |

Transporter length | ~2200mm |

Belt | polyurethane |

Detection method | magnetic induction |

Detection sensitivity | Fe from Ø 1.5 mm |

Adjustment and programming | max. 128 pulses per zone |

Signaling | optical-acoustic |

Alarm method | Belt stop and reverse (option) |

Pollution zone indicator | |

The speed of the conveyor belt is adjustable | 10-32m/min |

Power supply | AC230V, 50HZ |

Dimensions | 2000 mm x 3058 mm x 1220mm |

Weight | 420 kg |

MAIN FEATURES

- liquid crystal display with touch screen,

- built-in detection zone indicator enables precise location of contamination in the form of e.g. needle shards or other ferromagnetic metals,

- the ability to individually adjust the sensitivity for each zone, which enables automatic detection of single and bulk pollutants,

- intelligent event reporting system for RS-232 link. to the printer (included),

- automatic learning of the tested product with the analysis of the external background. This system eliminates the impact of the product and the environment on the stability of work to the maximum extent,

- alarm - optical and acoustic signaling, with or without stopping the belt, optionally reversing the belt with the product,

- touch panel, friendly and easy to use all functions in the form of described icons,

menu in Polish and English.