PARAMETERS

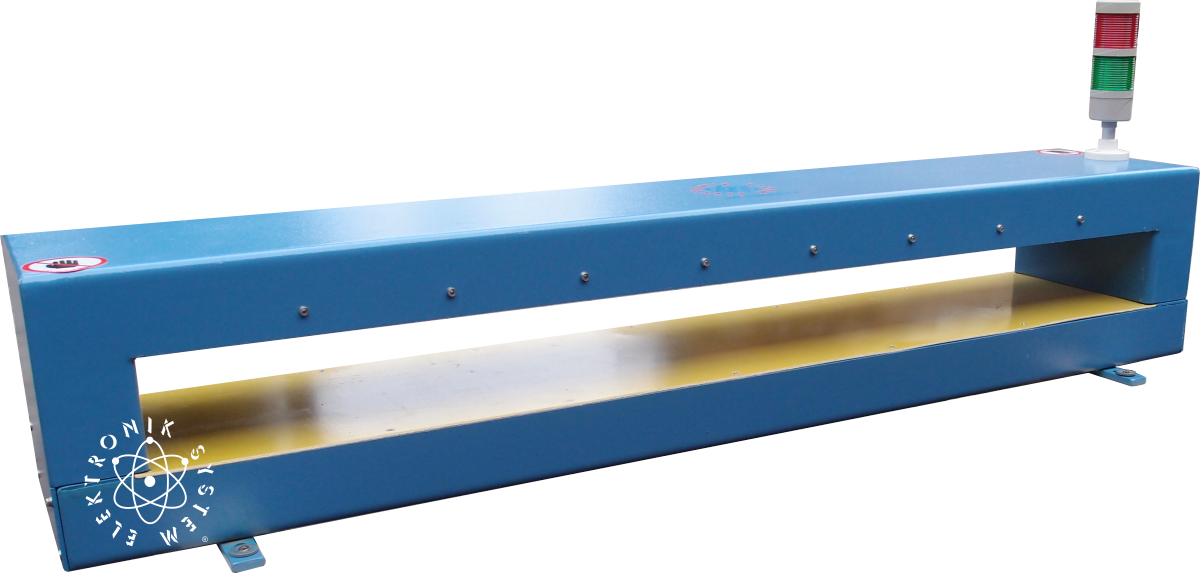

Model | ELEKTRON-NMD-P-1500-250 |

Detection working height | 250 mm |

Detection working width | 1500 mm |

Detection method | magnetic induction |

Detection sensitivity | Fe from Ø 0.8 mm |

Signaling | optical-acoustic |

The speed of the conveyor belt is adjustable | 0-35m/min |

Power | AC100-230V, 50HZ |

Built-in stabilized power supply | 170W |

Dimensions | 1800 mm x 260 mm x 400mm |

Weight | 190 kg |

MAIN FEATURES

- very easy and friendly operation of the detector thanks to the transparent operator panel,

- probe LEDs located on the detection probe, which indicate the exact location of the contamination. The solution allows you to save working time and test material,

- smooth and simple sensitivity adjustment,

- real-time (dynamic) detection,

- solid construction resistant to work in industrial conditions,

- in the case of contamination of the tested product with iron from 0.8, the indicator will indicate its presence,

- the LED on the probe housing will indicate the contamination zone,

- the detector has an output for controlling external devices (e.g. conveyor belt)